Typical thread inspection systems measure only the presence of threads and take a single reading during the inspection cycle. They provide so little information concerning the overall quality of the thread and hole. Automation Innovation monitors the entire inspection cycle - from the lead-in chamfer to the bottom of the threaded hole - for precise in-process quality information.

Automation Innovation uses statistical methods to perform 100% part and process verification. No simple set uniform boundaries here! Boundaries for each point along the inspection cycle are calculated based upon that point's process variation - large process variations produce wider boundaries than more repeatable process points.

Automation Innovation has engineered specially designed capacitive probes with 360 degrees sensing fields that form a “doughnut-shaped” inspection ring around the probe. This unique design allows the probe to measure only the thread or hole quality while ignoring the bottom of the hole even when the probe is just 0.010 inches from the bottom.

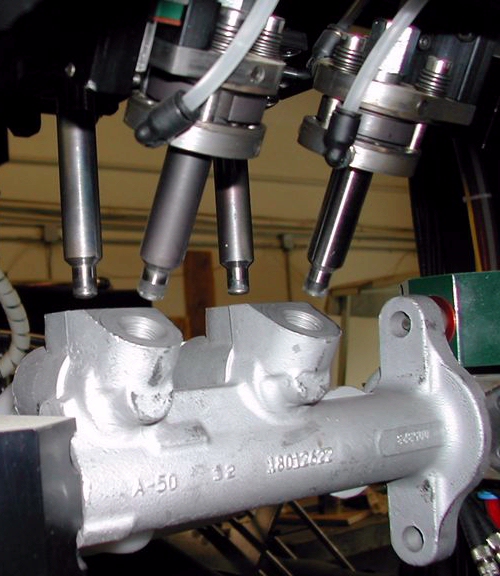

Automation Innovation has developed a system that can operate 8 different sensors synchronously or asynchronously. That means you can use one system to inspect 8 holes in one part (same cycle) or a hole in 8 separate parts on different machines (different cycles). The system is expandable to operate up to 512 sensors synchronously. Custom systems are available upon request.

Automation Innovation offers a FREE part evaluation program to its customers. Send in your good and bad parts and receive back color graphs showing how well your defects are distinguished from good quality parts.

|